Optimize Your Operations

Rapid Impact Solutions

- Fast time to value

- Deploys in hours and days, not weeks and months

- Non-Invasive

- Deploys without interfering with the process

- Intuitive user interface

- Available on prem and cloud based

- Available on prem and cloud based

The Process

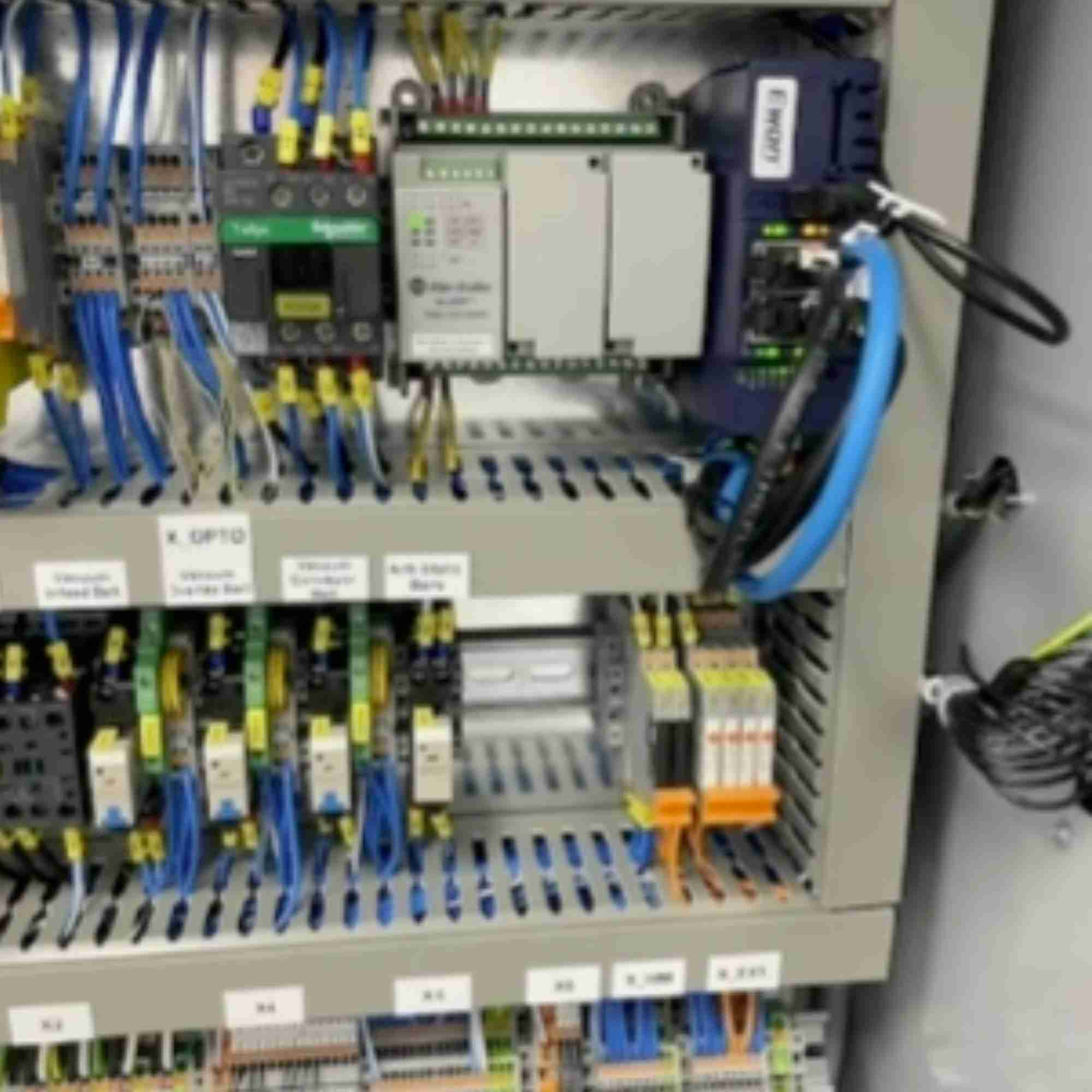

Rapid Data On-ramping

Seamlessly transition into the digital age with our rapid data on-ramping solutions. We provide a complete suite of advanced sensors designed to capture critical data from your operations. Our edge devices ensure that this data is efficiently collected and forwarded, while our local HMI (Human-Machine Interface) solutions give your operators real-time visibility into the processes, enabling them to make informed decisions quickly.

Rapid Data Aggregation

Harness the power of your data with our robust aggregation services. We help you collect, aggregate, and normalize meaningful data from multiple sources, ensuring that the information is consistent and actionable. Whether you prefer on-premises solutions or cloud-based repositories, our systems can integrate seamlessly with your existing ERP systems, providing a unified view of your operations.

Rapid Data Value

Turn your data into actionable insights with our data value services. We wrap context around your data, transforming raw information into valuable, actionable intelligence. Our team of experts will work with you to create compelling business cases and uncover hidden value within your operations, driving innovation and efficiency.

Asset Monitoring

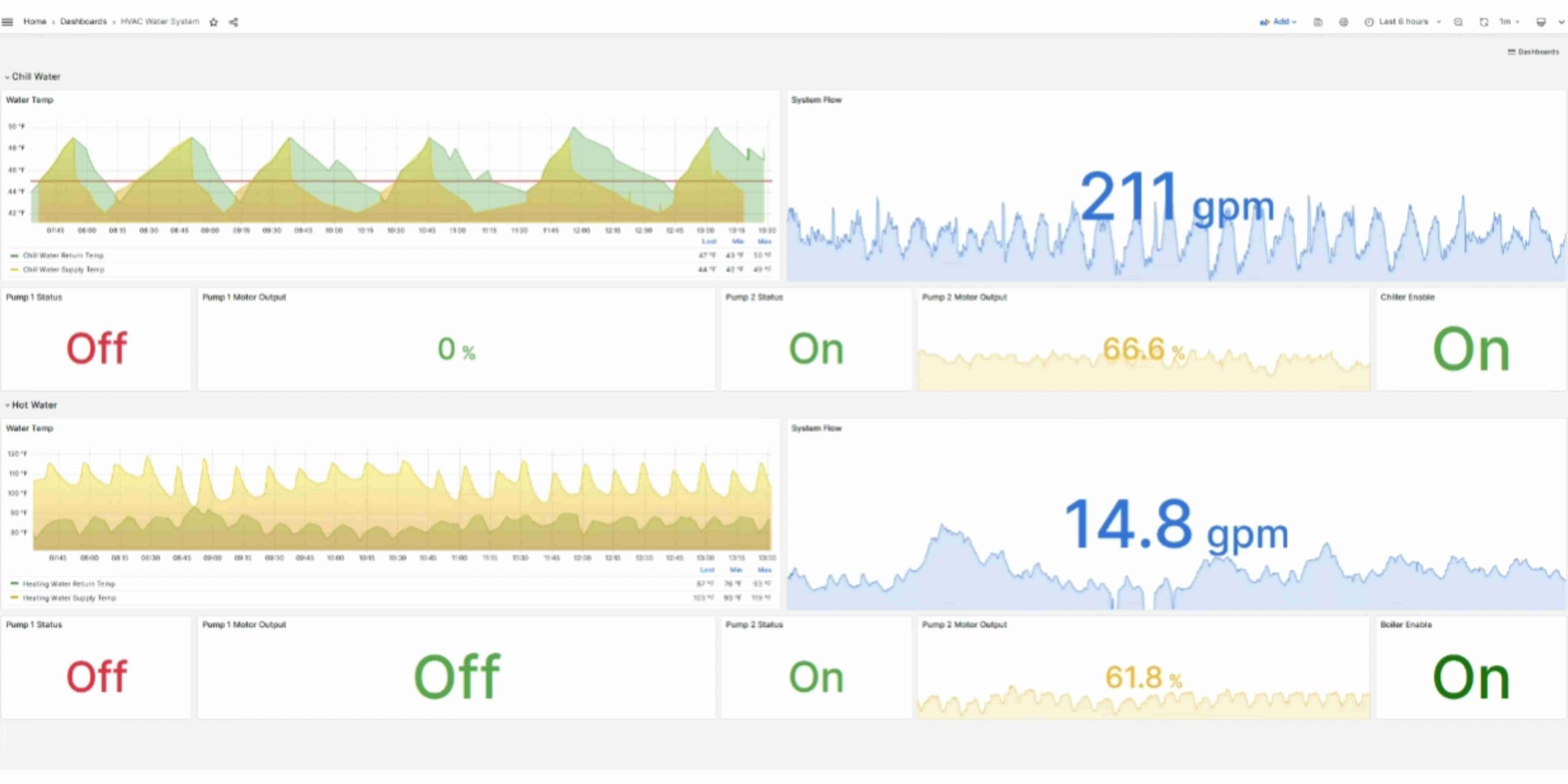

HVAC / Compressor/ Chiller

Machine Tools

Stamping / Press Machines

Die Casting

Injection Molding

Metal Forming

Band saw

Kiln

Conveyor System

Industrial Robots

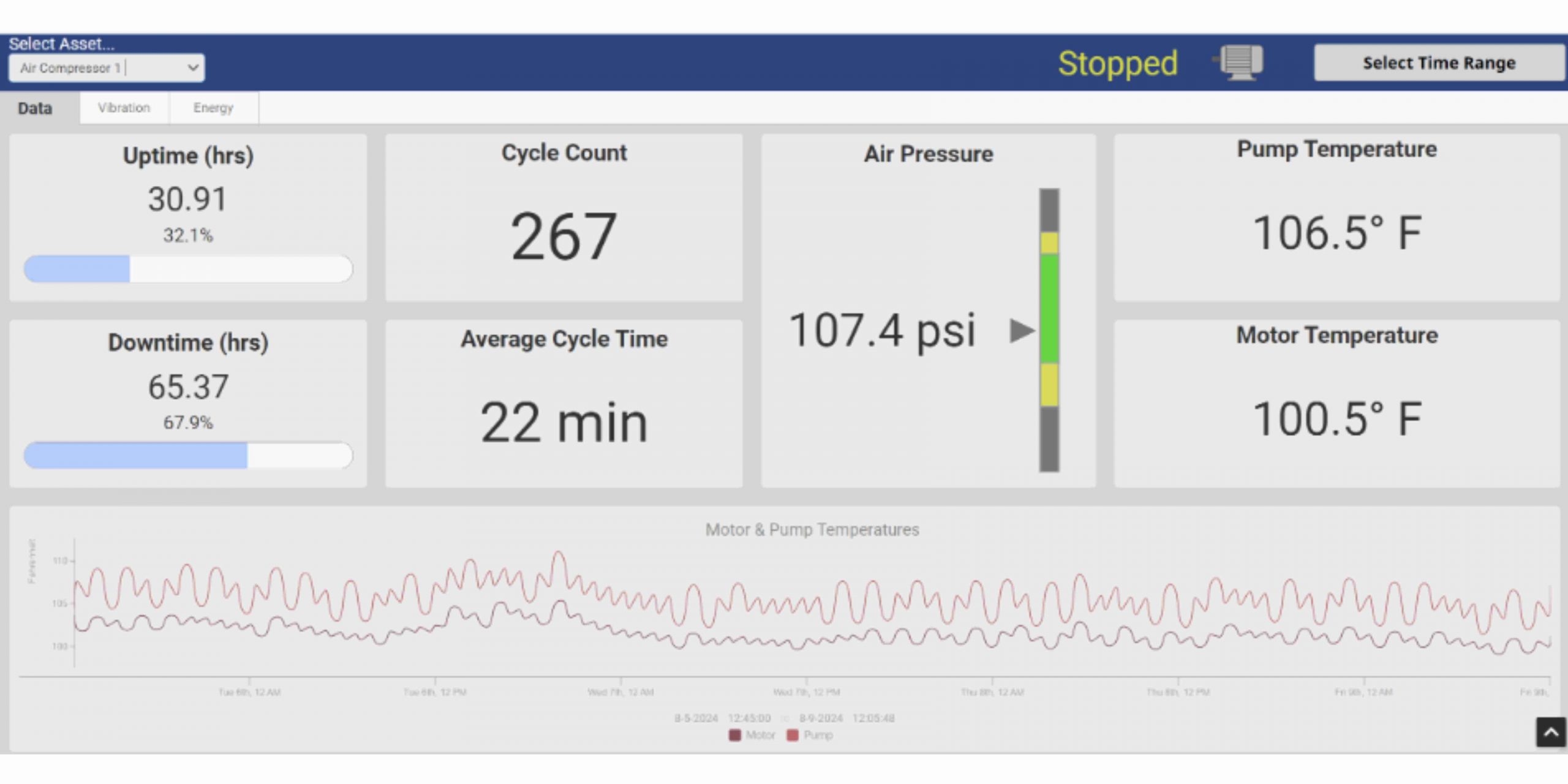

Compressor Monitoring

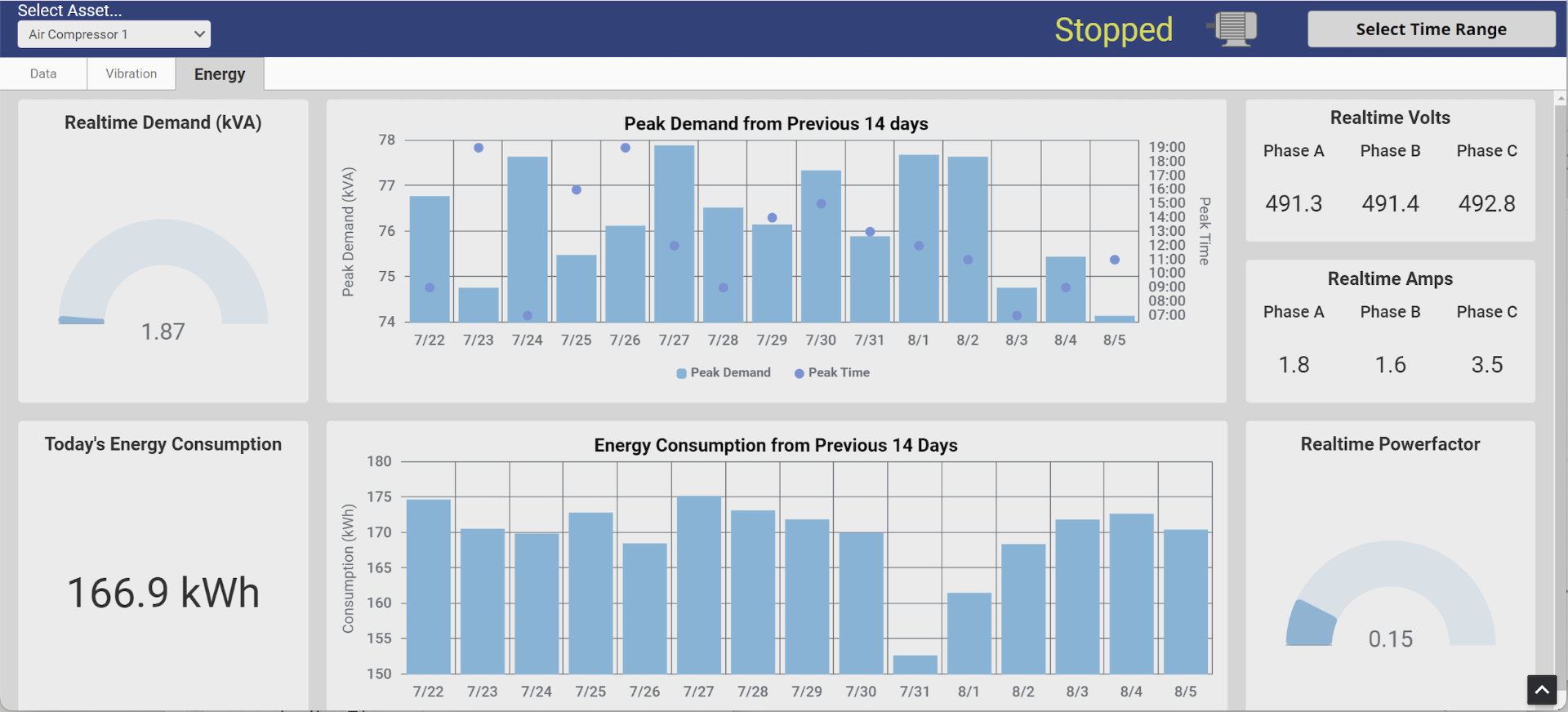

Energy Monitoring

Pump Monitoring

Compressor Monitoring

Monitoring the vibration and current draw of air compressors offers significant benefits in maintaining the efficiency and longevity of this critical equipment. Vibration monitoring allows for early detection of mechanical issues, such as imbalances, misalignments, or worn-out bearings. By identifying these problems before they escalate, facilities can prevent unplanned downtime and costly repairs. Regular monitoring helps ensure that the compressor operates within optimal parameters, reducing wear and tear and extending its lifespan. This proactive approach minimizes disruptions to production, maintaining a steady flow of operations and reducing the total cost of ownership.

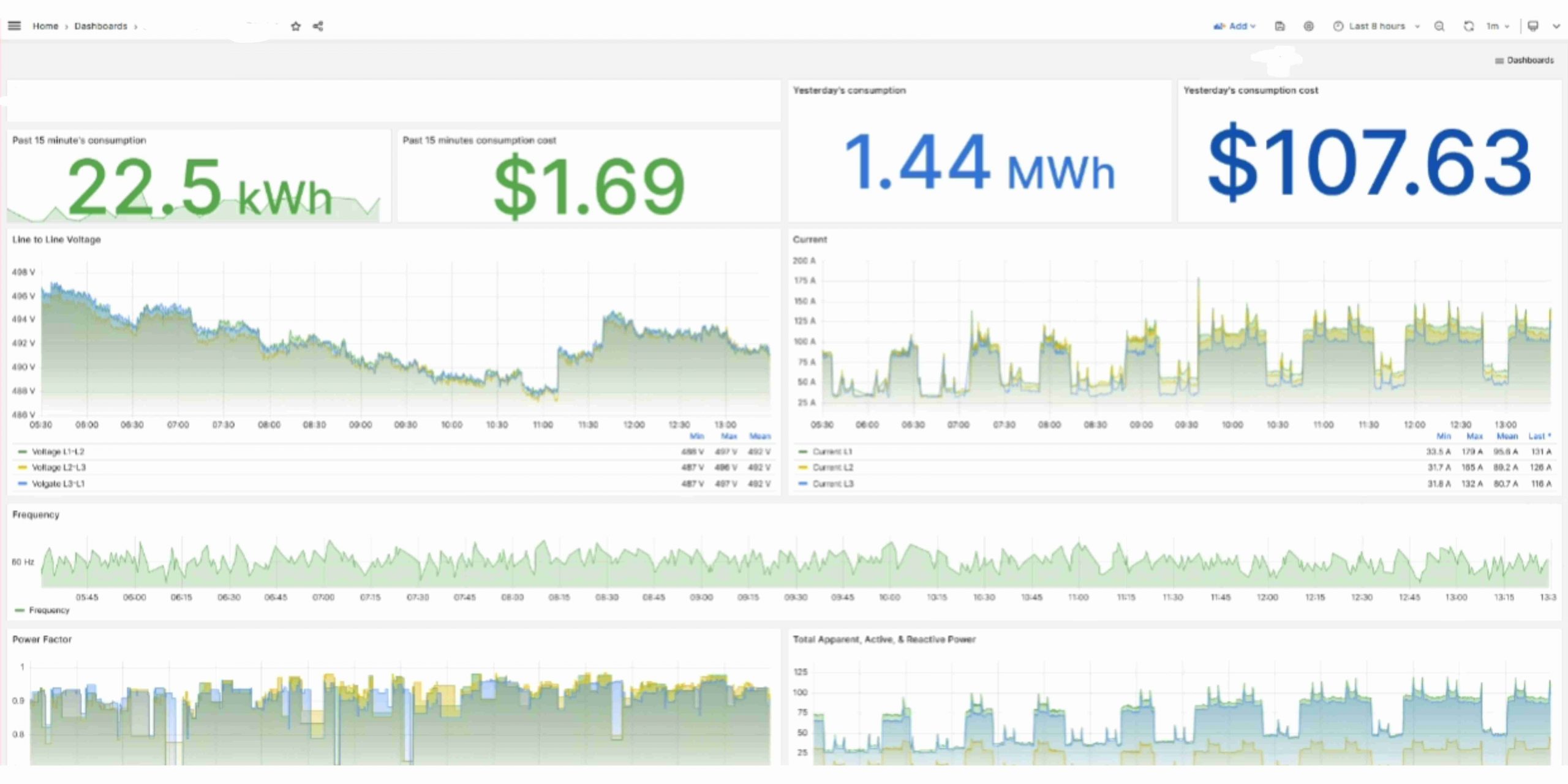

Energy Monitoring

In today’s competitive environment t’s critical for Manufacturers to proactively optimize energy efficiency. It is also true that it is difficult to optimize energy consumption without putting in place a system to accurately measure usage. Whether it be the total facility’s usage or submetering to be able to allocate costs to specific portions of the process, we have a solution.

Pump Monitoring

Across many industries, and specifically in Water and Wastewater Treatment, large pumps are the critical components. Often these important assets are run till they fail. Axiom has a better approach. By monitoring Runtimes, Vibration, and Voltage & Current Draw, we can detect anomalies in their early stages and allow for remedial actions before there is a catastrophic failure.

Explore Our Technology

Improve Operational Efficiency With Axiom Rapid Impact Solutions

Reduce Downtime

Condition Based Maintenance

Improve Quality

Real-time Monitoring

Equipment Utilization

Track And Manage

Increase Profits

Increase Throughput

Ready to Transform Your Operations?

Contact us today for a custom quote and see how Axiom Systems can enhance your operational efficiency and maintenance management. Our team is ready to assist you with a tailored solution that meets your specific needs.